Surface Analysis Platform at the CIC energiGUNE is a laboratory equipped with state-of-the-art surface specific experimental techniques that can be used to analyze solid state materials, including thin films, powders, as well as polymers and, in some, cases even liquids.

Surface composition, electronic and atomic structure can be probed by combination of several complementary spectroscopic, diffraction and microscopic techniques: photoemission spectroscopy (XPS and UPS), Auger electron spectroscopy (AES), scanning Auger microscopy/scanning electron microscopy (SAM/SEM), Raman spectroscopy, near-field scanning optical microscopy (NSOM), tip enhanced Raman spectroscopy (TERS), ambient pressure scanning probe microscopy (STM and AFM).

The services are provided for research groups within the center as well as to the external users such as research centers or other public organizations, but also to private companies or individuals.

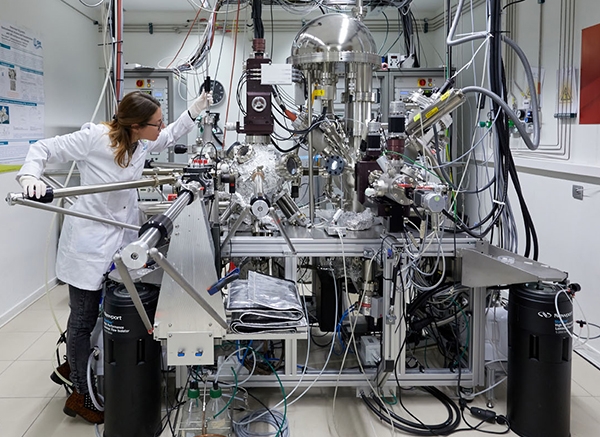

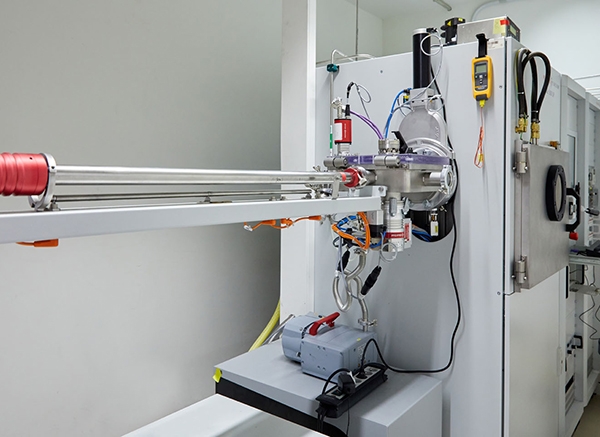

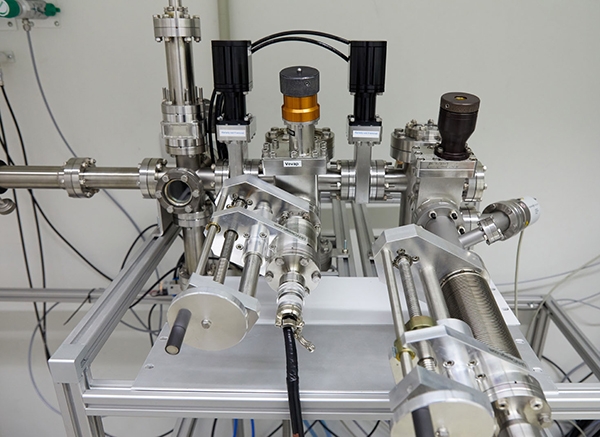

Multi Technique UHV Surface Analysis System for XPS, AES, SEM/SAM and depth profiling with high space and energy resolution on the different types of conducting and not conducting samples ranging from single crystals to polymers and powders. The system has a unique combination of methods for in-situ sample preparation and treatment provided by four e-beam evaporation sources in the Preparation Chamber, a high pressure cell and electrochemical cell. The analytical part of the system is a SPECS GmbH setup based on the hemispherical analyzer PHOIBOS 150, twin anode Al/Ag- X-ray source with monochromator FOCUS 500, fine focus electron gun with Schottky emitter for SEM/SAM, flood gun FG15/40 for charge compensation and small spot ion gun IQE 12/38 for ion treatment and precise depth profiling.

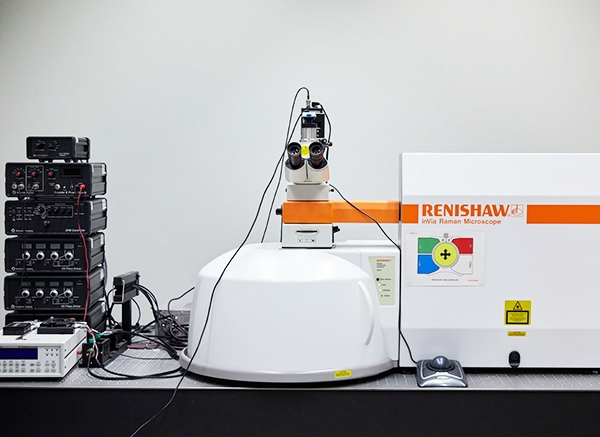

NANONICS MULTIVIEW 2000 TERS with RAMAN SPECTROMETER. SNOM microscope in transmission, in collection and reflection, atomic force microscope (AFM), non-contact mode, acoustic AC, LFM, MFM, Confocal Raman microscope and confocal microscope and optical.

This equipment allows the non-destructive characterization of nanostructures and interfaces in the materials used in batteries and supercapacitors via the study of chemical and physical properties with optical spectroscopy. This techniques will deliver advanced information of chemical bonds and other variables of the molecules. Raman spectroscopy is an important technique for the microscopic study of ceramic and polymeric materials that are commonly used as electrodes and electrolytes in batteries and supercapacitors.

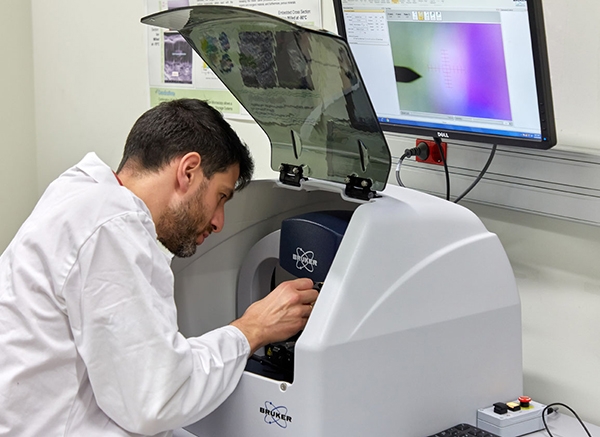

Stylus profilometry is a contact probe technique that provides information on the surface morphology of samples under study. This is of special interest when studying the thickness and roughness of conventional and thin film electrodes, as well as for solid electrolytes. These are the main technical specifications of the system:One- and two-dimensional surface profile measurements

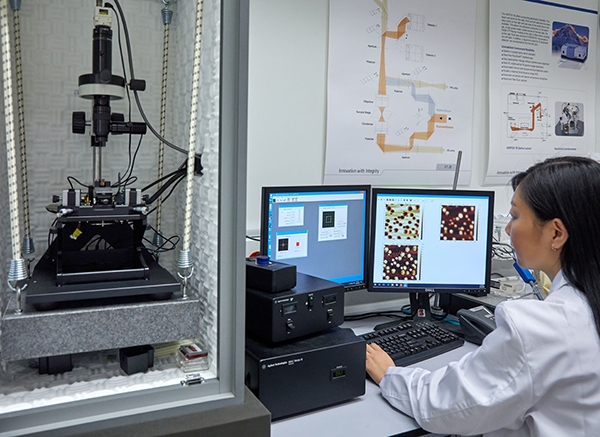

AFM/STM Microscope AGILENT 5500. Complete system for atomic force microscopy for samples of small and medium size, including: two independent scanners XY and Z, closed loop control for three axes, zero background curvature in the XY scanner, AFM head, direct optical in the Z axis, motorized focus in Z, motorized XY stage precision, electronic controller, software and cantilevers.

This equipment allows:

This deposition system is equipped with RF and DC magnetron heads that allow deposition at low temperature andversatility to evaporate materials of diverse nature (conductive metals, insulating ceramic type, ...), including materials with high melting point. The system has a fast entry chamber that can handle air sensitive samples.

Ultra high vacuum system to evaporate Li thin films from tens of nanometers up to tens of microns. Technical specifications are the following:

If you want to know the latest trends in energy storage and new developments in research, subscribe.

If you want to join a top-level team, collaborate with specialists in multiple disciplines or tell us about your concerns, don't think twice...